OKAN completes a wide range of engineering tasks:

initial technical requirements determination;

analysis and selection of technical decision concepts;

development of working design documentation according to unified design documentation system;

construction, strength and seismic analyses performance according to Rules and Standards of Atomic Energy Industry used in the Russian Federation;

hydro- and gasdynamic calculations performance according to Russian Standards;

development of acceptance and commissioning tests programs and methods;

qualification, acceptance and commissioning tests performance according to Procedural Guidelines and Standard Technical Documentation of Nuclear Facility;

assessment of compliance with Russian Regulatory Documents;

development of Quality Assurance for Safety in Nuclear Power Plants (equipment production and specification development) according to Russian Requirements;

test scope determination (destructive and non-destructive) according to Standard Technical Documentation of Nuclear Facility;

development and approval with Parent Material Organization (GMO) on quality Control Tables;

development of rationale for the use of import material, components or semi-finished product according to Russian Standards;

development and approval of Technical Requirements and Specifications;

development of operational and maintenance documentation;

certification according Russian Standards.

We always proceed from customer`s requirements and make upper limit efforts to find the most effective engineering on technical and economic indicators.

Company production capacity includes the following:

development and issuance of production and technical tasks;

materials and components receiving inspection;

mechanical handling, cladding, welding;

nondestructive testing performance;

equipment assembly;

initial, qualification and commissioning tests performance;

painting, preservation, marking and packaging.

Part of production works can be performed with the help of OKAN long-term partners depending on operation complexity.

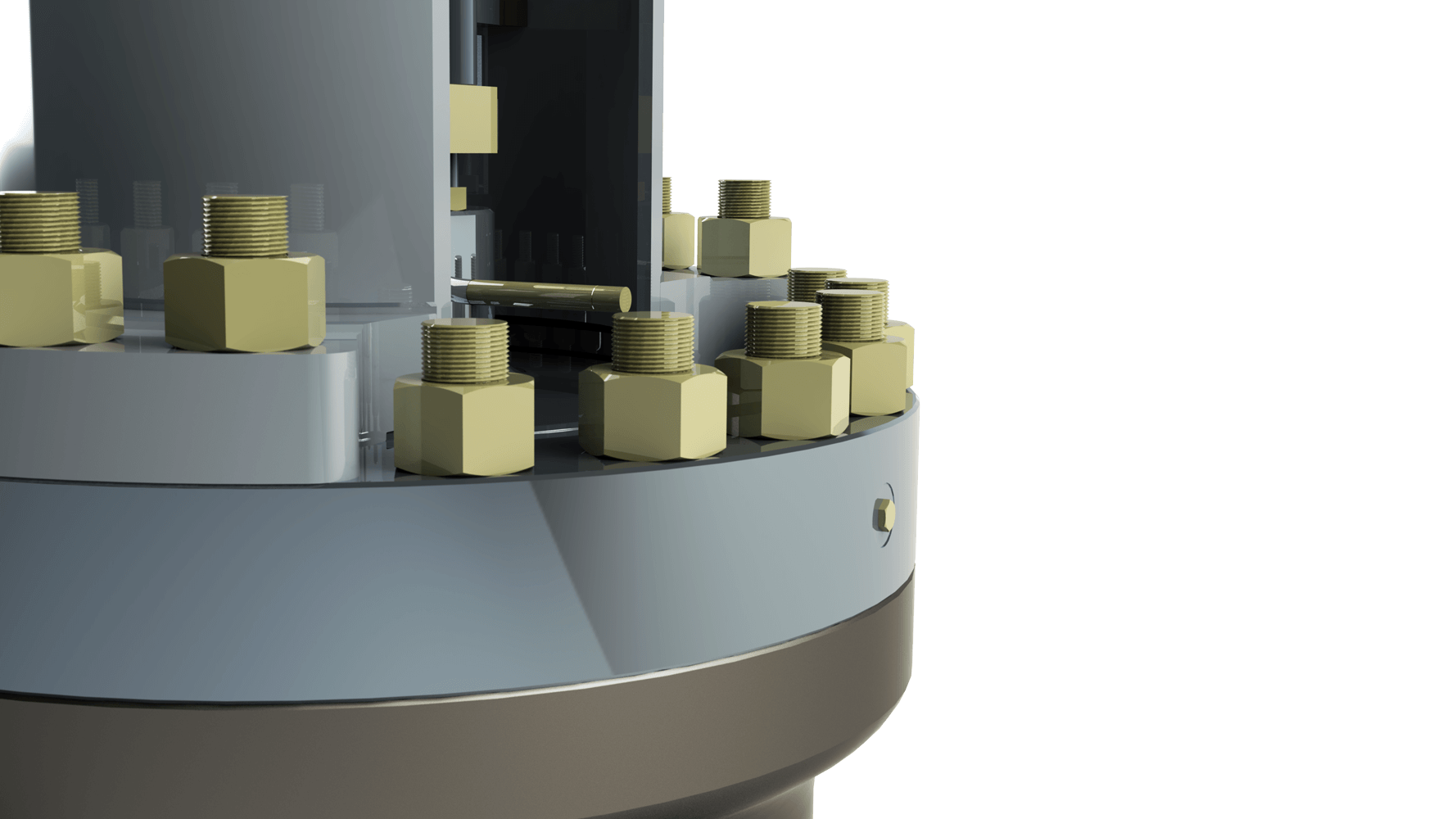

OKAN Maintenance Department has a great vision of delivered valves design and issues regarding their functioning. We guarantee to the Customer a prompt decision for all maintenance tasks.

OKAN Maintenance Department is responsible for:

supervised installation and adjustment;

valve and driving mechanism maintenance;

pull-out parts replacement;

service life prolongation;

valves inspection and conclusion development regarding replacement or repair;

modernization and reconstruction;

stand-by power supply restoration and combination;

parts manufacturing in full accordance with parts of operated valves.

Taking into account the significance of supplied equipment towards nuclear facility safe operation OKAN Maintenance Department preparedness for immediate response to any Operating Organization's call and request is a high priority value.

Regardless of any circumstances our specialists visit the object next day after the call.